Valve Condition and Performance Monitoring Enters a New Era

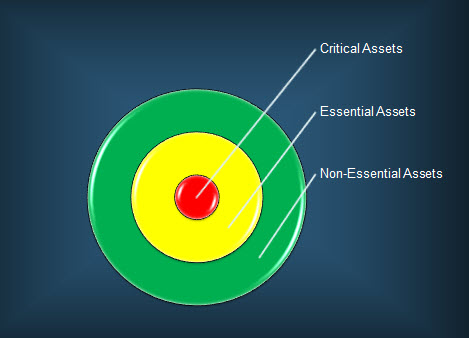

Monitoring the condition of critical valves such as Emergency Shutdown Valves (ESDVs), Process Shutdown Valves (PSDVs), High Integrity Pressure Protection Systems Valves (HIPPS), Blow-Down Valves (BDVs) and Pressure Safety Valves (PSVs) on both onshore and offshore Oil & Gas installations, is an essential part of ensuring the safety of personnel as well as the protection of the environment and process plant capital assets.

In today’s process industries, there is an increasing pressure on plant operators and owners to comply with operational safety, quality and integrity standards such as IEC 61508/61511, ANSI/ISA-84.00.01, ISO 55,000, ISO 9001:2015 and of course to respond to (for example) the UK HSE’s recent KP4 Audit findings in relation to ageing and life extension (ALE) – and the continuing safe operation of ageing assets (plant and equipment).

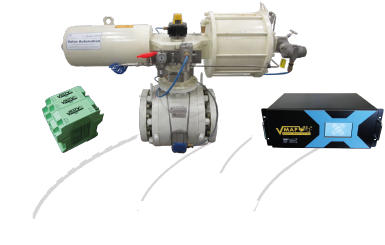

The failure of any Safety Integrated System (SIS) or other critical valve to operate on demand, or fail to provide a shut off, will have a major impact in any process. To demonstrate that all critical valves’ performance meets the installation’s safety criteria, they are normally subjected to routines involving inspection, partial closure, full closure, and leakage tests. These routines often require special test equipment and trained personnel, and will involve an expensive planned shutdown, thereby exposing the owners / operators to safety risks as well as interrupting production / generating losses.